R&D / New Businesses

Contribute to enjoyable lifestyles Achieve sustainable society

SAKATA INX’s unique technoglies are used in not only environmentally-friendly printing ink, but also in inkjet ink, powder toner, pigment dispersion for color filter, functional coating material etc. based on our core technologies: Resin Synthesis, Dispersion & Processing, Printing & Coating Evaluation technologies.

These technologies are also used to develop high-function compound material for the electronics industry.

Furthermore, in order to address the challenges such as "advancement of communication technology", "making lighter-weight mobility", "low carbon society" and "plastic-free society", we are focusing on the four chemical fields of "electronics chemicals", "optochemicals", "energy chemicals", and "environment & biochemicals" as well as open innovation with universities and other industries.

We will continue to develop products responding to global companies’ requests and meeting local needs. We will also provide best-in-class technologies and support to our customers.

Research & Development

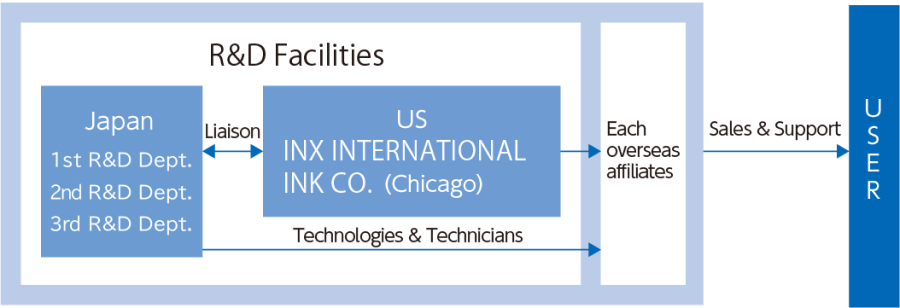

Organization Research & Development Structure

-

Corporate R&D Div.

Our 1st, 2nd, and 3rd R&D Departments work on the development and improvement not only of a range of printing inks but also of digital printing inks such as inkjet inks, powder toner for copiers, functional coating agents, pigment dispersion for color filters, and products in other existing businesses. As well as this, they also work on a range of other research with the target of developing new business in four chemical fields.

Furthermore, the Development Planning Department undertakes activities such as surveys and planning for the development of new products and new business, and the development of new markets.

The R&D Management Department manages the content of research and intellectual property, and surveys and planning concerning new development.

-

Technical Service & Development Dept.

The division works to gain an accurate picture of market needs and trends, and in collaboration with the sales division, goes directly to customers to find out what their requirements are in order to develop and improve products and provide technology support.

-

INX INTERNATIONAL INK CO. R&D Center(U.S.A.)

With a Corporate R&D Division in the US (Chicago), SAKATA INX develops products for Europe and North America, including a range of printing inks and inkjet inks.

Technology Core Technologies

-

Resin Synthesis Technology

To add coloring disperse function, adhesive function, printability, various durabilities and functions to binder resin used in ink.

-

Dispersion and Processing Technology

To minutely disperse organic, inorganic pigments, etc. from submicron to nano-level. This technology is applied in fields such as printing inks, inkjet inks, recording materials, functional coating agents, and optical and functional materials for the electronics industry.

-

Printing and Coating Evaluation Technology

To form thin film image to convey information or functional thin films to base material (paper, film, etc.).

-

Color Management Technology

To manage colors as absolute values by using spectrophotometers and computers.

-

Image Processing Technology

To process, store and transmit digital information into a wide variety of information formats with a computer.

Development Content of Development

-

Printing Inks

Gravure inks and Flexo inks are required to have the range of functions that are needed for packaging, and to possess high-speed printability while ensuring high print quality. Offset inks and Newspaper inks that offer the high quality and high-definition required for paper media and information media, and possess high-speed printability while offering excellent workability. SAKATA INX works to develop and improve this range of printing inks. As well as a range of coatings to improve functionality and printability, we also work on the development of coatings that add functionalities such as water and oil resistance, moisture proofing, anti-slip, gloss, press-on and easy peel properties, gas barrier properties, and antibacterial and antiviral properties. Our research and development of these products is premised on safety during printing and materials that are kind to the environment.

-

Digital & Specialty Products

Leveraging the foundational technologies that we have built up over the course of many years of ink development, we work on the research, development, and improvement of digital printing materials such as industrial inkjet inks and powder toner for copiers, and of pigment dispersion for color filters on LCD displays. For inkjet inks, we are developing inks with high quality and stable printability through ultra-fine dispersion of pigments on the nano scale in line with the high image quality and the increase in the level of detail that printers are increasingly capable of. As well as this, we also work on the development of other products such as functional coating agents for a wide variety of electronic components, and electronics chemical materials.

About Our New business

Organization field of initiatives

In order to address challenges such as advancing communications technology, making lighter vehicles, and moving away from plastics, we are focusing our efforts on the four chemical fields of electronics chemicals, optochemicals, energy chemicals, and environment & biochemicals while working with universities and other industries on open innovation.

Environment &

Biochemicals

Energy Chemicals

Electronics Chemicals

Optochemicals

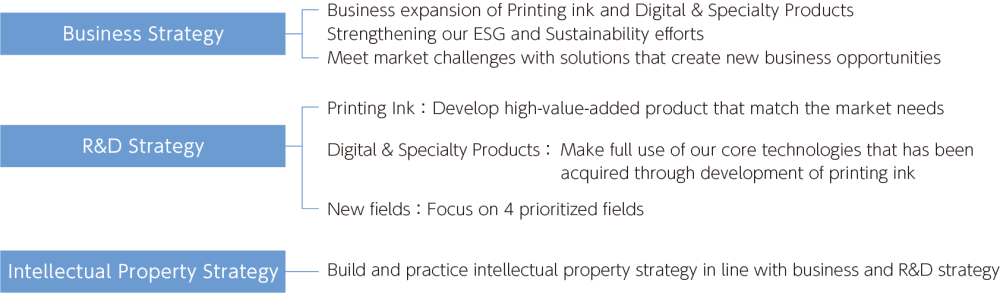

About Our Intellectual Property

To contribute to the overall development of society, SAKATA INX Group make efforts by actively creating, utilizing and protecting intellectual property. We aim to practice intellectual property strategy based on integration of business and R&D strategy in the entire group so that we can secure competitiveness and enhance corporate values.

-

Intellectual Property Strategy

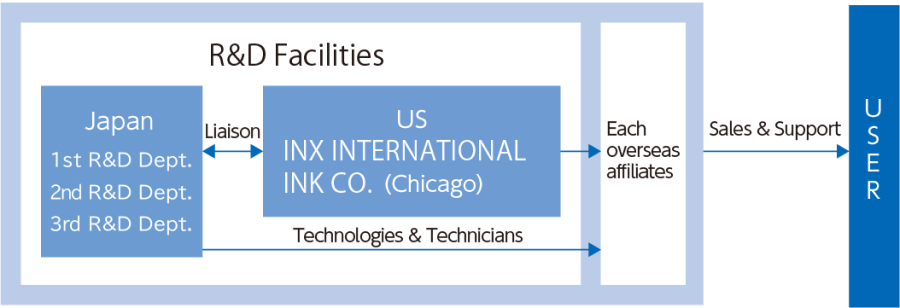

Our R&D Management Dept. takes the leading role of intellectual property strategy. They mainly handle patents and trademarks, and also provides education to R&D staffs in regards to intellectual property. Japan’s R&D takes the initiative in the R&D since it is positioned as the mother R&D. There are 3 R&D departments located in Tokyo and Osaka plant suited to its purpose. In order to deploy and promote R&D and intellectual property strategy globally in the entire group, Japan’s R&D is in liaison with INX INTERNATIONAL INK CO.'s R&D, consolidated subsidiary located in the US. Japanese technicians are stationed in each overseas affiliates, and technologies from Japan are coached and trained to local staffs. We provide global support to users by developing products that are tailored to the characteristics for customers operating globally and distinctive commodities in each region, etc.

▼Integration of 3 strategies

▼R&D Structure

Inquiries regarding R&D / New Businesses

-

Email inquiries